WELCOME TO DYNAMIC INDUSTRIALS- Arrowcon Brand

of Conveyor System

Conveyor Systems with Rampwalker Display

"Timely delivery of quality

products and services" is our commitment and our company culture is

evolved around this mission.

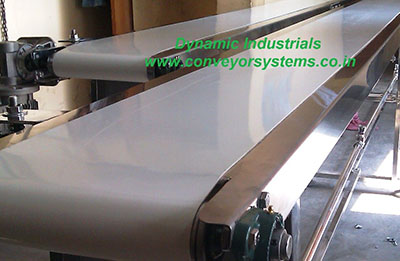

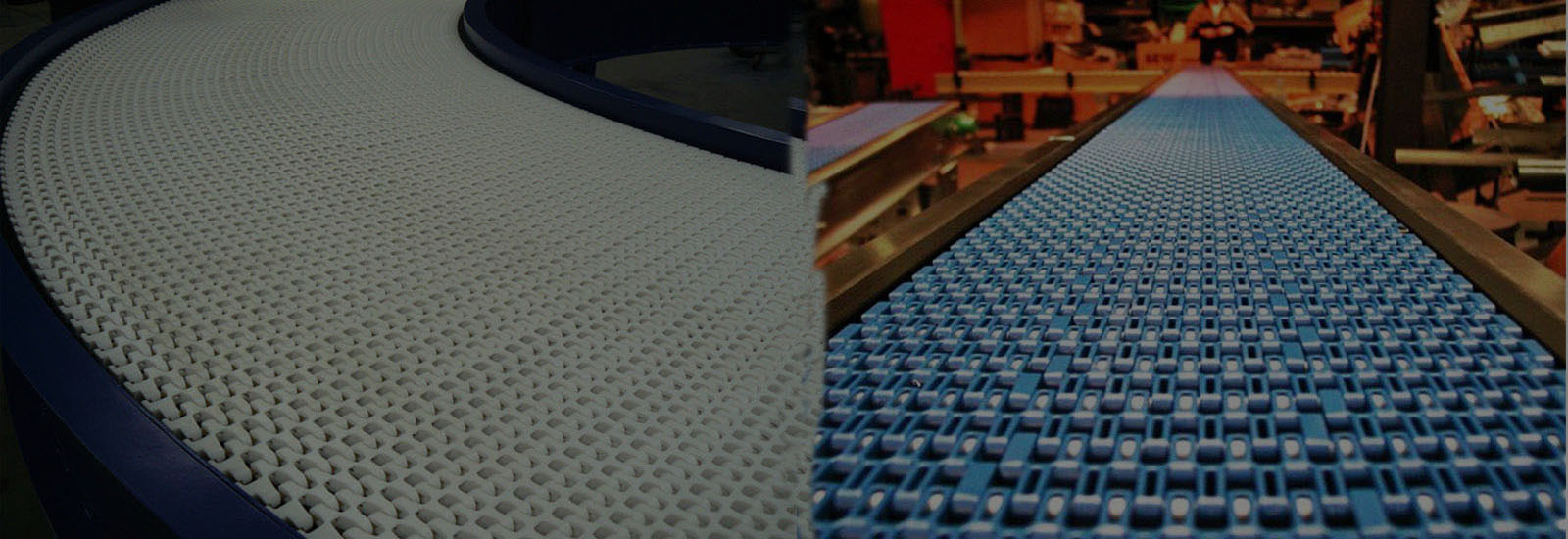

A conveyor system is a mechanism helping conveying of

almost all types of material from one (or more) input points to one

(or more) outfeed points. With the growing automation, Arrowcon

conveyor systems in India from Dynamic Industrial

have now gained popularity in many industries for Material transfers

in

Warehousing and logistics, automotive, electronic, food

processing, food packaging, home appliances, electrnic gadgets,

pharmaceuticals, chemical, textiles, Bakeries, woodworking and

plyboard manufacturing, bottling and canning, print finishing,

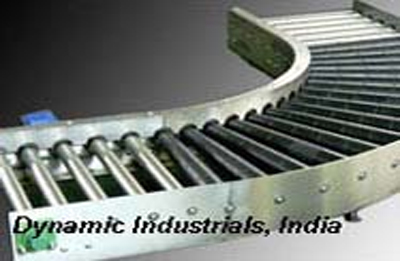

packaging and so on. Although a wide variety of materials can be

conveyed, some of the most common include packaged or unpacked

foods, raw or processed, bottles and cans, cloth rolls, automotive

components, metals, pills and powders, wood and furniture, cartons

or bags, electronic or electricals, vehicles for assemblies etc.

Rampwalker Display Conveyor Systems are innovative and visually captivating tools designed to enhance product displays in retail environments. These systems consist of a series of interconnecting ramps that create an eye-catching display surface where products can be showcased dynamically. The ramps are crafted from high-quality materials, ensuring durability and stability for both lightweight and heavier items. The gentle incline of the ramps allows products to glide smoothly along the conveyor system, creating a mesmerizing visual effect that attracts customers' attention instantly. Additionally, these conveyors can be customized with various designs, colors, and branding elements to align with any store's aesthetic or promotional campaign. With their sleek appearance and ability to showcase products in an engaging manner, Rampwalker Display Conveyor Systems provide retailers with an effective means to stand out from competitors while increasing customer engagement within their stores.

Dynamic Industrials

bags the National Icon Award for “The most promising Industrial

conveyor and Sushi conveyor Manufacturer”

Dynamic Industrials

bags the National Icon Award for “The most promising Industrial

conveyor and Sushi conveyor Manufacturer” Storage &

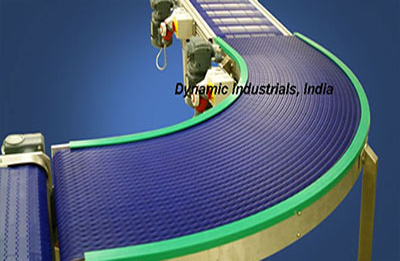

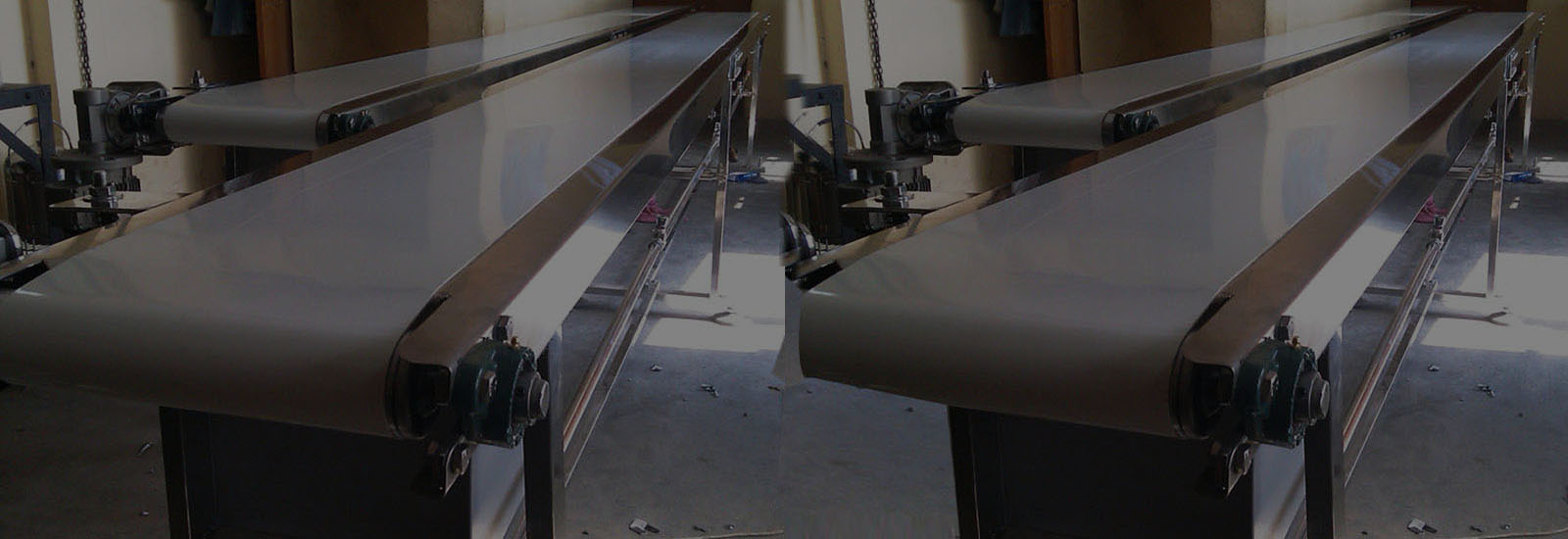

Warehousing, Manufacturing/Assembly Lines, Automotive,

Fashion/Retail, Paint & Finishing Lines,

Storage &

Warehousing, Manufacturing/Assembly Lines, Automotive,

Fashion/Retail, Paint & Finishing Lines,  our conveyors are equipped with built-in safety

features enabling safety of employees who directly interface with

the equipment.

our conveyors are equipped with built-in safety

features enabling safety of employees who directly interface with

the equipment.