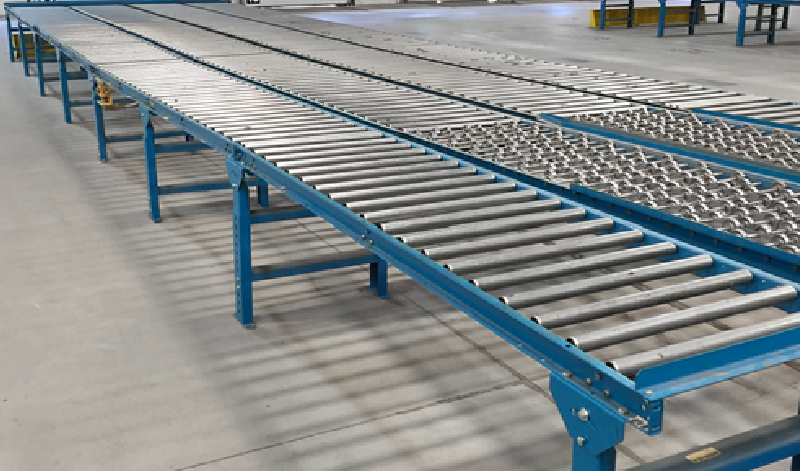

Arrowcon Gravity Roller Conveyors are engineered for smooth, efficient, and maintenance-free transportation of goods using gravity power or manual push. Ideal for warehouses, packaging, assembly lines, and logistics centres across India, these conveyors support cartons, pallets, totes, and more with minimal operator effort.

Optimized for packaging, warehousing, distribution, and assembly where reliable non-motorized material flow reduces labor and energy costs. Perfect for inspection zones, loading docks, and temporary or permanent conveyor setups.

As part of Dynamic Industrials’ Arrowcon range, these conveyors come with customizable options and nationwide service, providing reliable, scalable solutions tailored for Indian manufacturing and logistics.

Contact Arrowcon for expert-designed gravity roller conveyor systems that maximize operational efficiency and minimize costs.

Dynamic Industrial – Powering India's Logistics with Energy-Free Roller Conveyor Solutions

Simplicity | Durability | Efficiency